Table of Contents

Have you ever wondered how complex machines can produce precise parts for cars, planes, or electronics? The secret lies in CNC Full Form, which stands for Computer Numerical Control. CNC technology has transformed modern manufacturing, allowing for automation, precision, and efficiency like never before.

In this blog post, we’ll dive deep into the CNC full form, its history, applications, and why it’s so important. This guide is tailored for students looking to understand CNC technology in simple terms, making it easy to grasp the core concepts. By the end of this post, you’ll have a clear understanding of CNC, how it works, and where it’s used.

Did you know that in 2023, the global CNC machine market was valued at a staggering USD 26.61 billion, and it’s projected to reach USD 37.84 billion by 2028? This incredible growth underscores the transformative impact of CNC technology on modern manufacturing.

What is the CNC Full Form?

The CNC full form is Computer Numerical Control. In simpler terms, CNC refers to a computerized system that controls machine tools and equipment. These machines can perform tasks like cutting, milling, drilling, and shaping with extreme precision, all thanks to computerized instructions.

CNC machines follow a series of commands, often called G-codes, which dictate the movement and function of the machine. The operator feeds these instructions into the machine’s control unit, and the CNC machine executes the task without any manual intervention.

A Brief History of CNC

The concept of Computer Numerical Control (Full Form of CNC machine) dates back to the 1940s and 1950s when manufacturers began using punched cards to control machines. These early versions were called Numerical Control (NC) machines. With the development of computers, these machines evolved into what we now know as CNC machines.

By the 1970s, CNC machines became more widespread due to the availability of microprocessors, making the technology more efficient, affordable, and easier to implement.

How Does CNC Work?

At its core, CNC technology is quite simple. A computer controls the motion of a machine tool using programmed instructions. Here’s a step-by-step breakdown of how CNC works:

- Design Creation: The process begins with a design, often created using Computer-Aided Design (CAD) software. This digital design serves as the blueprint for the part or object to be made.

- Conversion to G-code: The CAD design is then converted into G-code, which is the programming language CNC machines understand. G-codes instruct the machine on how fast to move, where to cut, and the path it should take.

- Machine Setup: The operator sets up the material and tools on the CNC machine. Once the setup is complete, the machine is ready to start the manufacturing process.

- Execution: The CNC machine follows the G-code commands to execute the task. Whether it’s drilling, milling, or cutting, the CNC system precisely follows the instructions without any manual adjustments.

1. Key Components of CNC Machines

- Control Unit: The brain of the CNC machine that processes G-code and sends signals to the machine’s motors.

- Machine Tools: These include cutting tools, drills, or mills used to shape the material.

- Worktable: The surface where the material is placed during the operation.

2. The Importance of CNC in Modern Manufacturing

Understanding the CNC full form is vital, especially in the context of modern manufacturing. Here are a few reasons why CNC technology is significant:

- Precision: CNC machines provide greater accuracy than manual operations, reducing human error and ensuring uniformity.

- Efficiency: They can operate continuously without fatigue, resulting in faster production rates.

- Versatility: CNC machines can handle various materials, including metals, plastics, and wood, making them adaptable for different industries.

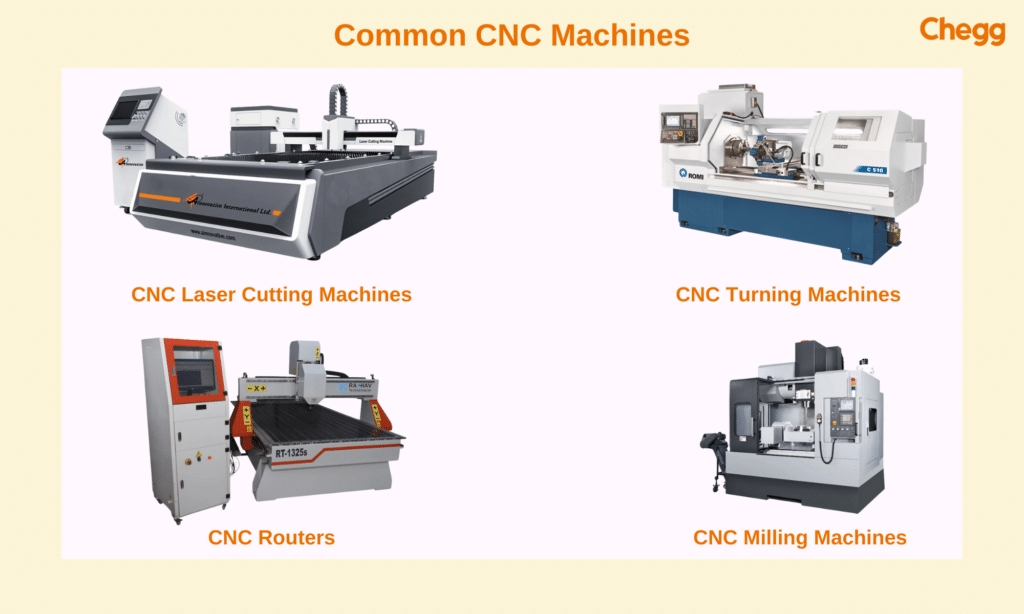

Types of CNC Machines

There are various types of CNC machines, each designed for specific tasks. Below are some of the most common types:

1. CNC Milling Machine

One of the most versatile CNC machines, it is used for cutting and shaping materials like metal, wood, or plastic. The milling machine uses rotary cutters to remove material.

2. CNC Lathe

A CNC lathe rotates the workpiece while a cutting tool shapes it. It is commonly used for producing cylindrical parts like shafts and bolts.

3. CNC Plasma Cutter

This machine uses a plasma torch to cut through metals. It’s often used in industries like automotive repair and construction.

4. CNC Router

Routers are primarily used for cutting wood, plastic, and soft metals. They are widely used in furniture manufacturing and woodworking.

5. CNC Laser Cutter

Laser cutting machines use a focused laser beam to cut materials like metal, wood, and plastic with extreme precision.

These are just some examples of CNC machines, each with unique abilities for specific manufacturing needs.

Applications of CNC Machines

CNC technology finds applications across various sectors, making it a crucial aspect of engineering education. Here are some noteworthy applications:

1. Manufacturing

CNC machines are integral in manufacturing components for various products. Industries such as automotive, aerospace, and electronics rely on CNC machining for creating intricate parts.

2. Woodworking

In woodworking, CNC routers are utilized to carve designs and create complex shapes. This automation allows for intricate patterns to be cut with high precision, often used in furniture and cabinetry.

3. Prototyping

For product development, CNC machines enable rapid prototyping. This allows engineers and designers to test their ideas quickly, leading to faster innovation cycles.

4. Medical Sector

CNC technology plays a vital role in producing medical devices, surgical instruments, and prosthetic components, where precision is paramount.

5. Education

Many technical and engineering schools incorporate CNC training into their curriculum, allowing students to understand modern manufacturing techniques practically.

Benefits of Using CNC Technology

Understanding the benefits of CNC machines will help you appreciate their importance. The following points outline the key advantages:

1. High Precision and Accuracy

CNC tools operate with mechanical precision, ensuring that each product is manufactured to exact specifications. This is essential for industries where flaws can lead to safety hazards.

2. Reduced Waste

Since CNC machines operate with a high degree of accuracy, they minimize material waste. This contributes to cost savings and conserves resources.

3. Automation and Efficiency

CNC machining reduces the need for manual labor in repetitive tasks, allowing skilled workers to focus on more complex projects. Consequently, production times can be significantly reduced.

4. Safety

By automating many functions, CNC machining enhances workplace safety. Operators are less exposed to hazardous tools and may oversee multiple machines simultaneously.

5. Customization

CNC machines can be programmed to create custom parts tailored to individual project requirements. This adaptability is beneficial in industries with varied client needs.

How to Get Started with CNC

1. Understanding CNC Programming

To get hands-on with CNC technology, students must learn about programming. Here’s a basic framework:

- G-Code: This is the most common programming language for CNC machines. Learning G-code allows students to understand how commands are structured.

- CAD and CAM Software: Familiarizing yourself with CAD and CAM software is essential. Programs like AutoCAD and SolidWorks are widely used in the industry.

2. Online Resources for Learning CNC

- YouTube Tutorials: Many educators offer free video lessons on CNC machine operation and programming.

- Online Courses: Websites like Coursera and Udemy provide structured courses on CNC machining and programming.

- Community Forums: Platforms such as Reddit or CNCZone offer valuable insights from experienced CNC operators and engineers.

Key Terms Related to CNC

Understanding the CNC full form also involves familiarizing oneself with some related terms:

- G-Code: The programming language for CNC machines.

- CAD: Computer-Aided Design software used to create 2D and 3D designs.

- CAM: Computer-Aided Manufacturing software that converts CAD designs into machine instructions.

- Lathe: A machine for shaping materials by means of a rotating workpiece.

- Mill: A machine tool used for machining parts, often by rotating a cutting tool against a stationary workpiece.

CNC vs. Traditional Machining

While both CNC and traditional machining methods are used to shape materials, they operate quite differently. Let’s understand the difference between them. Here’s a brief comparison:

| Feature | CNC Machining | Traditional Machining |

|---|---|---|

| Precision | High precision due to automated process | Lower precision, depends on skill |

| Efficiency | High, capable of 24/7 operation | Lower, requires manual intervention |

| Complexity | Can handle complex designs easily | Limited by operator skills |

| Material Waste | Minimizes waste | Higher waste due to manual error |

| Training Time | Requires learning CAD/CAM | Relatively shorter, hands-on practice |

CNC in Education and Future Trends

CNC technology is not just for industry professionals. Educational institutions are incorporating CNC training in their curriculum to prepare students for future careers in manufacturing. Many schools have started to use desktop CNC machines to teach students the basics of design and machining.

As for the future, CNC technology continues to evolve. The integration of Artificial Intelligence (AI) and machine learning is likely to make CNC machines smarter, allowing for predictive maintenance, real-time optimization, and even more precision.

CNC Full Form in Hindi

CNC machine full form in Hindi “कंप्यूटर न्यूमेरिकल कंट्रोल” CNC का फुल फॉर्म है। यह एक ऐसी तकनीक है जो मशीनों को कंप्यूटर द्वारा नियंत्रित करती है। CNC मशीनों का उपयोग मुख्य रूप से मैन्युफैक्चरिंग उद्योगों में किया जाता है, जहां मशीनें ऑटोमेटिक रूप से डिज़ाइन के अनुसार काम करती हैं। इस तकनीक में कंप्यूटर कोड के माध्यम से निर्देश दिए जाते हैं, जिससे धातु, लकड़ी, या प्लास्टिक जैसी सामग्रियों को सटीक आकार और डिज़ाइन में काटा या ढाला जा सकता है। CNC तकनीक का उपयोग कार, हवाई जहाज, और इलेक्ट्रॉनिक्स जैसे क्षेत्रों में बड़े पैमाने पर किया जाता है।

Conclusion

Understanding the CNC full form is essential for students interested in engineering and technology. CNC, or Computer Numerical Control, signifies a significant advancement in manufacturing, offering enhanced precision, efficiency, and customization. As industries continually evolve and demand more complex parts, the importance of CNC technology will only increase.

By exploring its applications, benefits, and operational methods, students can gain a comprehensive understanding that prepares them for the future job market. For those interested in diving deeper, numerous resources are available to hone your skills in CNC programming and machine operation.

CNC is not just a term; it is a gateway to future innovations and career opportunities in various fields.

Popular Full Forms

| HDD Full Form | USB Full Form | ALU Full Form |

| PCD Full Form | MCB Full Form | SIM Full Form |

| CRT Full Form | LCD Full Form | LED Full Form |

Ready to learn more? Click on thee following link to get the complete :- Full Form List

Frequently Asked Questions

Q: What is the full form of CNC?

The full form of CNC is “Computer Numerical Control.”

Q: What are the benefits of using CNC?

The benefits of using CNC include precision, automation, high efficiency, and reduced human error in manufacturing processes.

Q: What is a CNC used for?

CNC machines are used for automating and controlling tools like lathes, mills, and routers to produce complex parts with precision.

Q: What are the components of a CNC system?

Key components of a CNC system include the machine control unit, drive motors, feedback system, and machine tool.

Q: What are some common types of CNC machines?

Common types of CNC machines include CNC milling machines, CNC lathes, CNC routers, and CNC plasma cutters.

Q: What is the future of CNC technology?

The future of CNC technology involves advancements in automation, AI integration, and smart manufacturing, increasing efficiency and precision.

Q: What is CNC programming?

CNC programming is the process of writing code to control CNC machines, dictating how tools move and operate to manufacture parts.

Q: What is the CNC machine price?

The price of a CNC machine can range from ₹2 lakh to ₹50 lakh or more, depending on the type, size, and specifications.

Q: Which is the best CNC machine in India?

Some of the best CNC machine brands in India include companies like Jyoti CNC, HMT, and Bharat Fritz Werner (BFW), known for their reliability and advanced features.

Got a question on this topic?