Quick Summary

Table of Contents

Copper from mining and refining has many uses in many fields and technologies. Renewable energy, construction, transportation, and electronics utilize copper. What, exactly, do we put copper into?

People have long utilized copper to craft tools and ornaments. It makes electronic components. Rajasthan, Jharkhand, and Gujarat produce copper. These occur near bornite and chalcopyrite copper ores. This article describes copper ores and their value. Let us start with India’s copper-rich regions.

Indian copper mine development shows creativity and skill. High-quality copper goods have long been abundant in India. These pieces are clearly the work of skilled craftspeople. Copper manufacturers in India display their mastery in metalworking. Coppersmiths made beautiful tools, statues, and jewellery. Repoussé and lost-wax casting designs are beautiful and functional.

Copperwork from the past has had a significant impact on the present. The use of copper ores has enabled a seamless blend of modern technology and traditional knowledge. Copper makes commerce art, and the extraction and utilization of copper ores have driven the expansion of transportation networks, connecting various regions and cultural communities. The growth of copper production in India, fueled by the availability of copper ores, showcases human creativity and ingenuity in advancing industries and cultural exchange.

Copper, extracted from ores like chalcopyrite and malachite, is a versatile metal with a wide range of applications. Here’s how this reddish-brown metal shapes our world:

In essence, copper’s unique properties have made it a cornerstone of human ingenuity, shaping everything from the gadgets we use daily to the infrastructure that keeps our world connected.

Different categories organize copper ores, classified based on the properties of minerals. The composition and appearance of copper ores are distinct, making each category unique. Various copper ore names reflect their specific characteristics, highlighting the diversity and significance of copper ores in industrial and cultural applications.

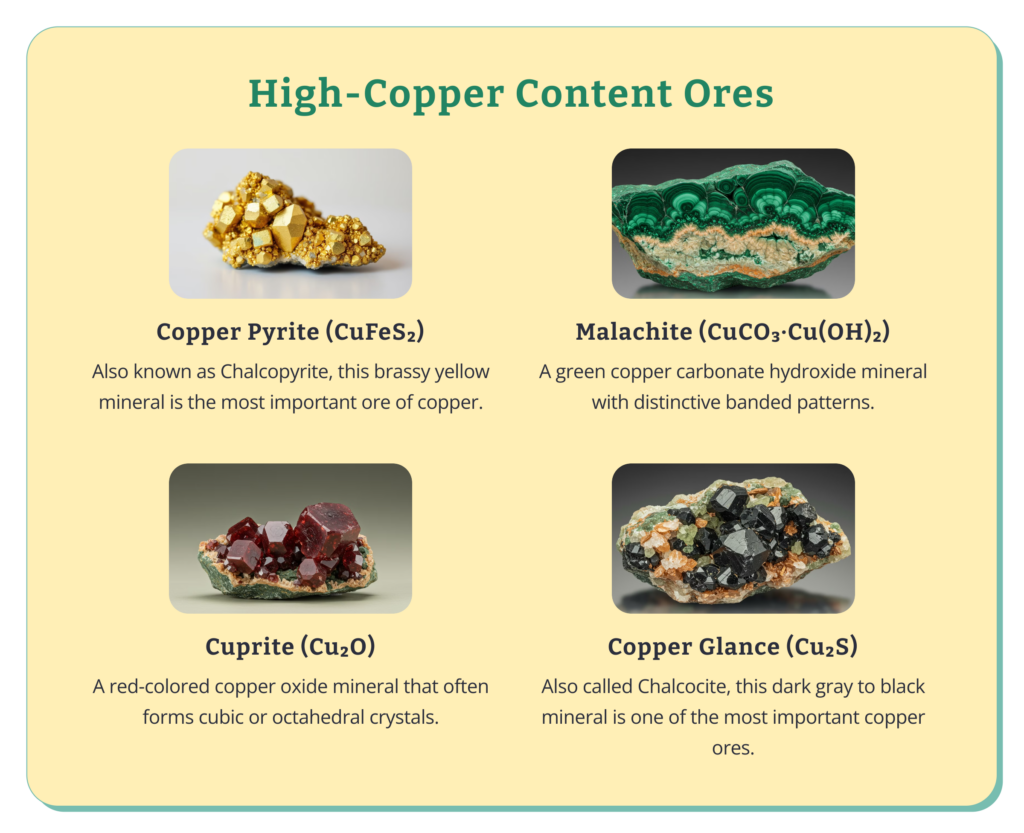

The most known copper ores are sulfide ores. They contain both copper and sulfur. The “yellow copper ore” chalcopyrite is a prime example. Froth flotation and smelting extract copper from these ores.

Copper is mined from ores like cuprite. Oxide ores contain copper in its oxidized state, either as oxides or hydroxides. Two famous copper oxides are malachite and azurite. Leaching or solvent extraction can extract copper from these ores.

When oxide and sulfide ores are found together, they are referred to as “mixed ore.” They present special difficulties. The abundance of different minerals in them contributes to this. Copper extraction from complex ores is a multi-step process.

Copper, a vital metal used for everything from electronics to plumbing, is extracted from rocks called ores. Here are some of the main copper ores:

Copper ores play a vital role in supplying the copper used in electronics and wiring, powering smartphones and computers. Known for its excellent thermal conductivity, copper, derived from copper ores, is essential for appliances like refrigerators, stoves, and toasters. Copper pipes, made from processed copper ores, enhance water quality and resist corrosion, ensuring durability. Additionally, its antibacterial properties are widely utilized in hospitals, contributing to a cleaner and safer environment.

Roofs, walls, and ornaments all look better when copper is used.

Thus, the structure appears more attractive. Solar panels and other renewable energy require copper conductivity. Transportation wiring and other components use copper. Copper is essential to modern life. Its versatility, durability, and longevity improve living conditions, prosperity, and technology.

Many manufacturing processes use copper. It is worldwide but concentrated by geology.

Chile produces copper among the world’s best. Country has abundant Andean resources. Chuquicamata and Escondido mines keep Chile as a copper leader.

Peru’s massive Andean copper deposits follow. Cerro Verde and Antamina, the world’s largest mines, aid growth. It produces more copper than any other country. The country is a treasure trove of untapped resources.

Copper deposits in Arizona are very large. It is central to the Copper Belt. The United States is now a major source of copper for the global market. Some examples of such mines are Bingham Canyon and Morenci.

| Country | Notable Copper Mines | Production (2021) |

|---|---|---|

| Chile | Chuquicamata, Escondida | 5.6 million metric tons |

| Peru | Cerro Verde, Antamina | 10.8% of global production |

| United States | Bingham Canyon, Morenci | Major global source |

1. Chilpi Series

This region spans parts of Balaghat and Chhindwara districts in Madhya Pradesh. It consists of quartzite, copper-pyrite, mica schist, and marble. Copper extracted from this area is utilized at the Malanjkhand Copper Plant.

2. Ghatsila

Situated in Jharkhand, this copper smelting facility employs electrolysis for refining and produces brass sheets. Additionally, it processes copper to extract gold, silver, and nickel.

3. Khetri

An integrated copper mining and refining plant in Jhunjhunu District, Rajasthan, established in 1967. It sources copper ore from Malanjkhand copper mines in Madhya Pradesh. The site also hosts a sulfuric acid plant and a fertilizer plant.

4. Malanjkhand

An open-cast copper mine located in Balaghat District, Madhya Pradesh, has erected a copper plant. It also dispatches copper ore from Malanjkhand to the Khetri Copper Plant in Rajasthan.

5. Rakha Initiative

The Rakha Copper Plant, situated in Singhbhum’s Rakha District, Jharkhand, sources copper ore locally from the Rakha mines.

6. Tajola

Located in Raigadh, Maharashtra, the Tajola Copper Plant imports copper cathodes and produces copper rods.

Copper mining and smelting are India’s main industries. Benefits include electronics, construction, and transportation. Copper mining and processing boost the economy. Furthermore, Hindustan Copper Limited is India’s largest copper producer, making it technologically advanced. Works include mines and factories. The domestic copper supply fails without it. Rajasthan, Madhya Pradesh, and Jharkhand produce most copper in India. This should increase Indian copper production.

Copper mines in India vary according to the state of the market, the level of demand worldwide, and technical improvements. Mining, beneficiation, smelting, and refining are the steps in the production process. The largest producer of copper in India follows these steps. They guarantee high-quality, adaptable metal. India is improving mining safety and efficiency. This work is crucial. Copper production has increased, which is good. They keep their industrial relevance.

Some complex methods extract copper from its ores. Metal for various industries is made from the raw material. Critical smelting, refining, mining, and beneficiation methods are helpful. The two main mining methods used to extract copper ores are open-pit and underground. The copper mineral reserves are accessed using blasting and excavation methods, followed by transportation to processing facilities.

Beneficiation is the process of removing beneficial minerals from the ore matrix. Reconcentrating copper-bearing minerals increases ore copper content. Froth flotation, gravity, and magnetic separation methods are employed. After beneficiation, concentrated copper ore undergoes smelting to extract the metal from its mineral form. High temperatures are applied during smelting. It is done to concentrate to separate the copper from the impurities and create a copper matte. Methods like electrorefining refinement purify the copper. This copper is pure enough for industry.

Copper is essential due to its many uses. These examples demonstrate its versatility and importance.

Copper is chosen for electrical wiring, cables, and conductors because of its high conductivity. Copper’s high efficiency cuts down on power loss from the power plant to the outlets. It enhances the efficiency of utilizing the power grid.

Plumbing systems benefit from copper. Because of its antibacterial and decay-resistant properties.

Copper pipes, fittings, and valves ensure the guarantee of clean water. Copper roofing is strong and attractive.

The malleability and ductility of copper make it an excellent material for creative uses. Sculptures, decorations, and jewellery use the desirable reddish-gold color. Copper conducts heat in heat exchangers, cookware, and machinery.

Also Read :-

Environmental damage from copper mining, processing, and use. Sustainable practices minimise harm and ensure resource availability. Copper consumption and environmental protection must balance. Copper producers conserve natural resources and operate sustainably.

Copper mining pollutes water, soil, and habitats. Additional greenhouse gas emissions occur. Throwing away trash can harm the environment. Energy-intensive smelting releases carbon into the atmosphere.

Businesses are solving these issues with sustainability. Energy efficiency, waste management, and ethical mining practices are necessary. Recycling copper reduces extraction. This helps the environment.

Copper, a metal prized for its conductivity and versatility, doesn’t exist in pure form underground. Instead, we find it hidden within various minerals called copper ores. Let’s explore some of the most common ones:

Copper ore exists in a variety of mineral forms, most commonly as sulfides, oxides, and carbonates. The amount of copper it contains can vary widely, from a trace amount (less than 1%) to over half its weight (50%). Despite this variation, copper ore generally shares some key characteristics:

Mining companies are looking for new ways to supply copper as global demand rises. Deep-sea mining and technology are two potential topics for the future.

The value of reserves hidden beneath the ocean is rising. The reason for this is the exhaustion of Earth’s remaining copper deposits. Some of the minerals mined from the seafloor are polymetallic nodules that contain copper. They come from the ocean floor. Exploitation must address environmental and regulatory issues to survive.

New mining technologies boost efficiency, safety, and sustainability. Human vulnerability is minimized while maximizing efficiency. Using artificial intelligence, robotics, sensors, and big data techniques. The methods used to extract and refine the material have undergone developments.

Planning for the future demonstrates the industry’s commitment to satisfying customers.

India’s quest for self-sufficiency in critical minerals faces a roadblock with copper. Despite possessing total in-situ reserves estimated at 712.5 million tonnes, the actual metal content is a mere 9.4 million tonnes. This translates to a significant challenge: low-grade copper ore, averaging less than 1% metal content compared to the global average of 2.5%.

This scarcity necessitates imports to meet the growing domestic demand for copper in sectors like infrastructure, power generation, and renewable energy. The presence of major copper ore deposits in Singhbhum (Jharkhand), Balaghat (Madhya Pradesh), and Jhunjhunu and Alwar (Rajasthan) offers a glimmer of hope. However, efficiently extracting usable copper from these low-grade sources remains a hurdle for India’s mining industry.

Potential UPSC points to consider:

Electronics, plumbing, building, and industrial machinery use copper. It is superior conductivity, decay resistance, and adaptability.

Open-pit and underground mining processes get copper from copper mineral sources. Beneficiation leads to smelting and refining. It yields copper.

Copper extraction pollutes water, soil, and ecosystems and emits carbon. Power-hungry methods cause it.

Yes, copper recycling is quite successful. As a result, fresh mining is less necessary, and less power is consumed compared to primary production.

In the future, researchers must investigate deep-sea copper mining and implement automation and eco-friendly copper extraction methods.

Hot sulfur solutions deposit copper, often in volcanic areas, enriching rocks with concentrated copper to form copper ore.

Certainly! Malachite serves as a copper ore. This vibrant green mineral is a copper carbonate hydroxide with the chemical formula Cu2CO3(OH)2.

Authored by, Amay Mathur | Senior Editor

Amay Mathur is a business news reporter at Chegg.com. He previously worked for PCMag, Business Insider, The Messenger, and ZDNET as a reporter and copyeditor. His areas of coverage encompass tech, business, strategy, finance, and even space. He is a Columbia University graduate.

Editor's Recommendations

Chegg India does not ask for money to offer any opportunity with the company. We request you to be vigilant before sharing your personal and financial information with any third party. Beware of fraudulent activities claiming affiliation with our company and promising monetary rewards or benefits. Chegg India shall not be responsible for any losses resulting from such activities.

Chegg India does not ask for money to offer any opportunity with the company. We request you to be vigilant before sharing your personal and financial information with any third party. Beware of fraudulent activities claiming affiliation with our company and promising monetary rewards or benefits. Chegg India shall not be responsible for any losses resulting from such activities.